Screen Roll Selection

Screen Roll Selection

The result of this simulation shows that it is not possible, with a screen count of 120 L/cm (305 L/inch), to

meet the other screen roll specifications. The screen count has been reduced to 110 L/CM (279 L/Inch).

You might want to rethink the other targets. If the screen count has to be 120 L/cm then:

•

Reduce the Ink Film Thickness. This might result in not having a good full tone print or the need for

upgrading substrate specification. You might not have the option to change the screen roll for every job

so you need to have rolls in the machine fit for the majority of substrates you print on

•

Reducing the cell wall thickness. It might not be possible to be engraved by the screen roll supplier. He

indicated 10 µm was the minimum (This is just an assumption for this example)

•

Reduce the cell width to depth ratio. This might result in ink release problems and can cause quickly

clogging of the cells in the screen roll thus no ink is transferred from the screen roll to the print plate

It might be better to reduce the screen roll screen count in order to have a reliable process, printing a

consistent colour.

Following a cell depth calculation that shows how the cell depth changes when changing: line count, ink film

thickness and cell wall thickness. Check if your screen roll specification cell opening depth ration is >2.5

The result of this simulation shows that it is not possible, with a screen count of 120 L/cm (305 L/inch), to

meet the other screen roll specifications. The screen count has been reduced to 110 L/CM (279 L/Inch).

You might want to rethink the other targets. If the screen count has to be 120 L/cm then:

•

Reduce the Ink Film Thickness. This might result in not having a good full tone print or the need for

upgrading substrate specification. You might not have the option to change the screen roll for every job

so you need to have rolls in the machine fit for the majority of substrates you print on

•

Reducing the cell wall thickness. It might not be possible to be engraved by the screen roll supplier. He

indicated 10 µm was the minimum (This is just an assumption for this example)

•

Reduce the cell width to depth ratio. This might result in ink release problems and can cause quickly

clogging of the cells in the screen roll thus no ink is transferred from the screen roll to the print plate

It might be better to reduce the screen roll screen count in order to have a reliable process, printing a

consistent colour.

Following a cell depth calculation that shows how the cell depth changes when changing: line count, ink film

thickness and cell wall thickness. Check if your screen roll specification cell opening depth ration is >2.5

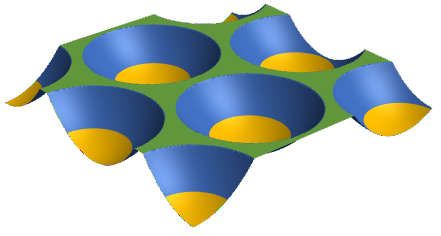

Hexagonal cell pattern

Hexagonal cell pattern

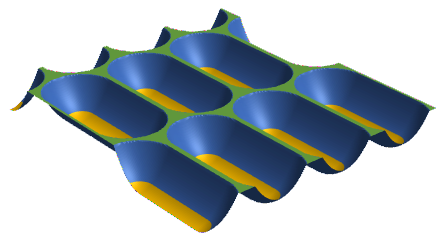

Extended cell pattern

Extended cell pattern

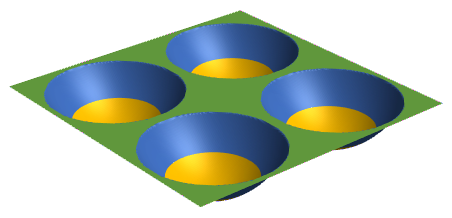

Reversed square cell pattern

Reversed square cell pattern

Contact Technology Coaching if you want more information or a quotation.

Contact Technology Coaching if you want more information or a quotation.

Technology Coaching has developed a new interactive module allowing you to check your

screen roll specifications before ordering screen rolls.

Assume you have been talking to your partners: • The Repro house claims you need for your jobs a 120 L/cm (305 L/inch) screen roll screen • The substrate supplier and ink supplier agree the need to use a screen roll Ink Film Thickness of 11 µm (5.9 BCM/inch²) • Your ink supplier advices a cell width to depth ratio of 1 : 2.5. This to be sure the ink is released from the cells and the cells can be cleaned • The screen roll manufacturer claims that the minimum cell wall thickness he can engrave is: 10 µm (0.0039 inch) The values can be entered in the Screen Roll Specification Checker.This video shows a simulation

The result of this simulation shows that it is not possible, with a screen count of 120 L/cm (305 L/inch), to

meet the other screen roll specifications. The screen count has been reduced to 110 L/CM (279 L/Inch).

You might want to rethink the other targets. If the screen count has to be 120 L/cm then:

•

Reduce the Ink Film Thickness. This might result in not having a good full tone print or the need for

upgrading substrate specification. You might not have the option to change the screen roll for every job

so you need to have rolls in the machine fit for the majority of substrates you print on

•

Reducing the cell wall thickness. It might not be possible to be engraved by the screen roll supplier. He

indicated 10 µm was the minimum (This is just an assumption for this example)

•

Reduce the cell width to depth ratio. This might result in ink release problems and can cause quickly

clogging of the cells in the screen roll thus no ink is transferred from the screen roll to the print plate

It might be better to reduce the screen roll screen count in order to have a reliable process, printing a

consistent colour.

Following a cell depth calculation that shows how the cell depth changes when changing: line count, ink film

thickness and cell wall thickness. Check if your screen roll specification cell opening depth ration is >2.5

The result of this simulation shows that it is not possible, with a screen count of 120 L/cm (305 L/inch), to

meet the other screen roll specifications. The screen count has been reduced to 110 L/CM (279 L/Inch).

You might want to rethink the other targets. If the screen count has to be 120 L/cm then:

•

Reduce the Ink Film Thickness. This might result in not having a good full tone print or the need for

upgrading substrate specification. You might not have the option to change the screen roll for every job

so you need to have rolls in the machine fit for the majority of substrates you print on

•

Reducing the cell wall thickness. It might not be possible to be engraved by the screen roll supplier. He

indicated 10 µm was the minimum (This is just an assumption for this example)

•

Reduce the cell width to depth ratio. This might result in ink release problems and can cause quickly

clogging of the cells in the screen roll thus no ink is transferred from the screen roll to the print plate

It might be better to reduce the screen roll screen count in order to have a reliable process, printing a

consistent colour.

Following a cell depth calculation that shows how the cell depth changes when changing: line count, ink film

thickness and cell wall thickness. Check if your screen roll specification cell opening depth ration is >2.5

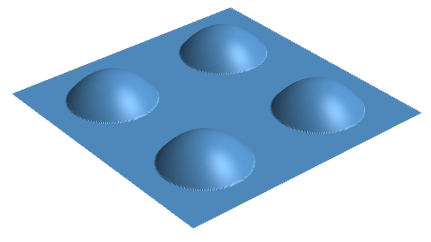

Screen roll engraving simulation are available for the following engraving types:

Square cell pattern Hexagonal cell pattern

Hexagonal cell pattern

Extended cell pattern

Extended cell pattern

Reversed square cell pattern

Reversed square cell pattern

Contact Technology Coaching if you want more information or a quotation.

Contact Technology Coaching if you want more information or a quotation.

Read more about screen roll inspection and selection in the following articles:

“An alternative for screen roll line count?”

International Paper Board Industry, September 2018“The real source of dot gain?”

International Paper Board Industry, July 2014“Unambiguous Conclusions of the Extended Cell Shape Performance”

Presented at CorrExpo conference (TAPPI), Indianapolis (USA), 8-9 October 2013“Unambiguous Conclusions of the Extended Cell Shape Performance”

Flexo & Gravure Global, March 2013“Performance conclusions of the EFlo extended cell shape from Pamarco”

International Paper Board Industry, March 2013“Choosing the best screen roll for your printing process”

FlexoTech, March 2009“The best screen roll for your print process. How do you specify it”

International Paper Board Industry, February 2009