Ink Stability

Ink Stability

Contact Technology Coaching if you want more information or a quotation.

Contact Technology Coaching if you want more information or a quotation.

Ink Stability is about the changes in viscosity and pH of water

based ink over time. The equipment for measuring pH and

viscosity in-line require maintenance and operator skills. pH

sensors need daily calibrating and replacement every 3 months in

order to provide a reliable reading. The Technology Coaching Ink

Stability test allows to measure the changes of water based ink pH

and viscosity over time resulting in defining an additive mixture

that is added on regular fixed time intervals resulting in a stable

ink without the need of measuring equipment.

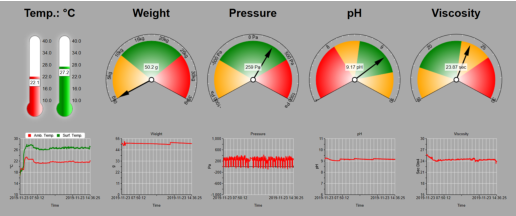

Why use the Technology Coaching Ink Stability Measuring test procedure? 1. You want to be sure that the ink always performs the same and is not deteriorating as a result of the time it is on the press. 2. The monitoring of ink properties is time consuming as the measuring equipment needs to be calibrated and maintained. Would it not be easier to just know how to compensate for the ink viscosity increase and pH drop by adding in fixed time intervals to the ink what evaporated? 3. It is easy to add a fixed quantity of the additive mixture on fixed time intervals as the additive mixture is depending on ink and machine properties and its quantity is related to the surface area of the screen roll and thus constant independent of the ink quantity in circulation. Next graph shows the in-line collected test data:

The result of using the Technology Coaching Ink Stability test

procedure:

• Delivering a consistent printed product to your customer • Optimum ink properties throughout the production run • Minimized waste during production • Consistent press return ink properties • Maximized productivity (Machine speed and uptime)

In addition we have developed a long-term ink stability test

specially used to evaluate the settling when using fillers in the

varnish. The next video shows 2 times four varnishes. The left

syringe of each set of two is the varnish after adding 20% water.

The video consists of 149 images. Every hour 1 image is taken and

shown 0.1 sec.

Contact Technology Coaching if you want more information or a quotation.

Contact Technology Coaching if you want more information or a quotation.

Read more about ink stability in the following articles:

“Ink properties and production”

International Paper Board Industry, March 2006“Ink properties and production”

FlexoTech, March 2006“Ink foaming of water based inks, what is the reason and can it be

resolved?”

FlexoTech, September 2006“Ink foaming - what is the reason and can it be resolved?”

International Paper Board Industry, September 2006“Ink foaming of water-based inks”

Flexo & Gravure Int’l, December 2006“Minimum printed dot size as a print capability measurement”

International Paper Board Industry, May 2006“Minimum printed dot size as a print capability measurement!”

Pira Conference “Ink on Paper”, 6th & 7th December 2006, Dublin