Ink & Glue Consumption

In-line Ink & Glue consumption

measuring

Contact Technology Coaching if you want more information or a quotation.

Contact Technology Coaching if you want more information or a quotation.

Measuring in-line flexo ink and glue consumption is possible on

any make or type of conversion equipment.

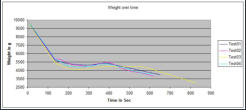

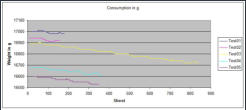

It provides the fundamental information needed to improve your production process. This information is missed when only installing glue detection or printed image inspection systems. Technology Coaching designed and build a special set-up and data collection algorithm allowing accurate measuring of ink and glue consumption while the machine is in production. Ink and glue consumption is recorded every product produced. This can be done simultaneously on different print stations. This is a typical glue consumption graph: Measuring glue consumption provides information about: • Glue add-on per product produced • Glue add-on per linear glue lash produced • If glue add-on is constant when changing speed • Speed measuring is part of the system This is a typical graph for ink consumption: Measuring ink consumption provides information about: • Ink used for ink system start-up • Ink foaming • Ink leakage during production • Impact on ink transfer when adding water (Viscosity and density kg/dm³) • Accurate figures for ink lay-down • Using different screen roll configurations • The ink transfer in relation to substrate used • Using different polymer materials • Using different inks (colours, varnishes suppliers) • Ink transfer when printing wet in wet • Ink transfer changing machine speed • Using different screen roll doctoring systems and materials In-line Ink and Glue consumption measuring will change your fundamental knowledge of these processes and helps you to produce a constant product level first time right! Contact Technology Coaching if you want more information or a quotation.

Contact Technology Coaching if you want more information or a quotation.

Read more about ink and glue consumption in the following

articles:

“The real source of dot gain?”

International Paper Board Industry, July 2014“Ink loss is only half the battle”

International Paper Board Industry, March 2013“Ink properties and production”

International Paper Board Industry, March 2006“Ink properties and production”

FlexoTech, March 2006