BoxAssess

BoxAssess: Box Gap, Panel

Alignment, Folding, Slotting and

Scoring Assessment

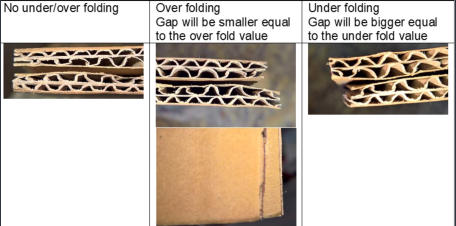

The following images explain the term “Under- and Over- Folding”:

The following images explain the term “Under- and Over- Folding”:

The equipment case containing:

o

GapJig with data cable

o

Calibration block

o

USB stick (Software and dongle)

o

Tool for removing GapJig Battery cap

The equipment case containing:

o

GapJig with data cable

o

Calibration block

o

USB stick (Software and dongle)

o

Tool for removing GapJig Battery cap

Contact Technology Coaching if you want more information or a quotation.

Contact Technology Coaching if you want more information or a quotation.

One of the box manufacturing industries headaches is the correct

aligning of a Flexo Folder Gluer. It is all about the correctly

manufacturing of the FEFCO 0201 a "RSC" regular corrugated

case.

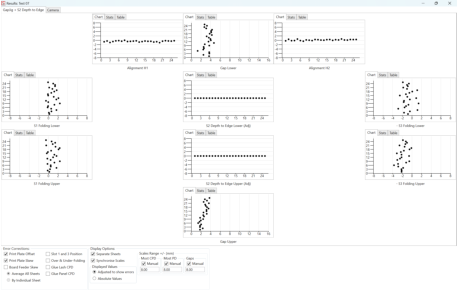

Technology Coaching has developed the test and evaluation procedure BoxAssess including the GapJig. BoxAssess allows to evaluate the feeding, slotting and folding of the board. New in this is that also over- and under- folding will be evaluated using the gap jig. The GapJig is also used for measuring gap and panel alignment. BoxAssess provides detailed information about the folding accuracy but also about feeding and slotting accuracy. Using this method allows to align all parts of the FFG. It minimizes waste and set- up time but it also helps to get a good box geometry which maximizes the box strength. BoxAssess will support you to improve your RSC quality and reduces waste thus saves the environment.This is a graphical example of the data results for slotting and

feeding.

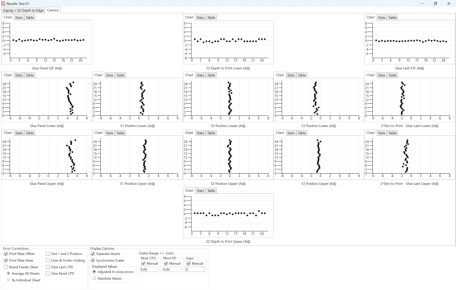

Also folding is evaluated. The graphs show gapfolding and panel

alignement variation.

The following images explain the term “Under- and Over- Folding”:

The following images explain the term “Under- and Over- Folding”:

The collected data allows identifying any problems in your FFG but

also what to do to correct them.

The equipment case containing:

o

GapJig with data cable

o

Calibration block

o

USB stick (Software and dongle)

o

Tool for removing GapJig Battery cap

The equipment case containing:

o

GapJig with data cable

o

Calibration block

o

USB stick (Software and dongle)

o

Tool for removing GapJig Battery cap

In addition to BoxAssess the “Gap Error Simulation” tool is

developed.

This tool allows to simulate the impact on the gap error of a folded box due to: o The misalignment of the slots o The skew of the board o The size of the box. Misalignment of the slots (the 2 outside slots) has 2 parts: 1. The cross production direction offset relative to the target position of the slot which is in the tool “Input error” section the first column “CPD offset” where the error can be set. 2. The offset between the lead edge knife and trail edge knife of a slot which is in the tool “Input error” section the second column “skew mm/m” where the error can be set. The centre slot (2) is the reference for the calculation yet this slot can also not be in the centreline of the machine too. The gap error calculations are based on not using a side-trim knife thus the glue panel skew represents also the board feed skew. Over- and under- folding is not separately included in the gap error calculation but has a similar impact on the gap as the error of slot 1 and 3 on the gap. A 1mm cross production direction move of slot 1 or 2 result in a 2 mm gap deviation where as an over- under- folding error of 1 mm results in a 1 mm gap deviation. The tool will give an inside on the size of the gap error due to not correct aligned slots and/or feeder. Click on the next image to start the tool

BoxAssess closed loop folding control

The next product we are developing is a folding control system using the latest 2D scanning sensor technology that allows to scan real time at full machine speed a 3D vectorised image by using AI software . Folding control can be implemented on any FFG and provides a closed loop between the sensor measured data and machine settings during box production. Benefits, depending on the FFG machine capabilities, are: • Zero defect folded boxes. • Reduced set-up time. • Reduced set-up waste. • No need using the side trim knife. • Higher production speeds. • Significant cost savings. The image right shows a RSC manufacturer joint real time scan from which the AI software is able to calculate the optimum machine settings for all machine parts involving folding.

Sheet-to-Sheet Flute shifting relative to score line

With BoxAssess it is possible to evaluate the impact of the sheet- to-sheet relative to the score line flute profile shifting on folding variation. The next simulation shows the problem of sheet-to-sheet relative to the score line flute profile shifting.

BoxAssess download

• Download Brochure Contact Technology Coaching if you want more information or a quotation.

Contact Technology Coaching if you want more information or a quotation.

Read more about folding variation in the following article:

“The Digitallab - Tools for corrugated”

International Paper Board Industry, February 2022“How to improve the folding of an RSC”

International Paper Board Industry, January 2012